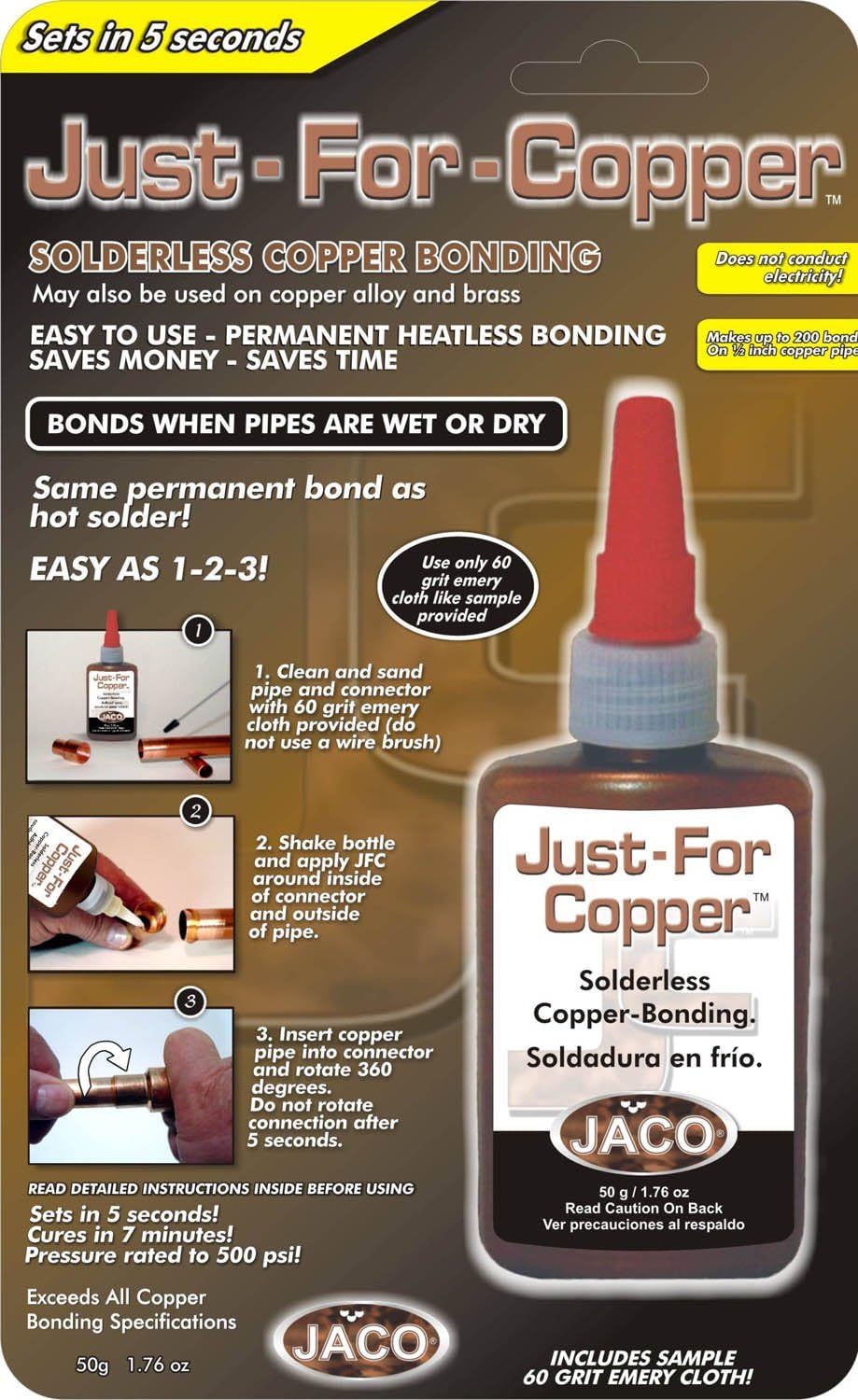

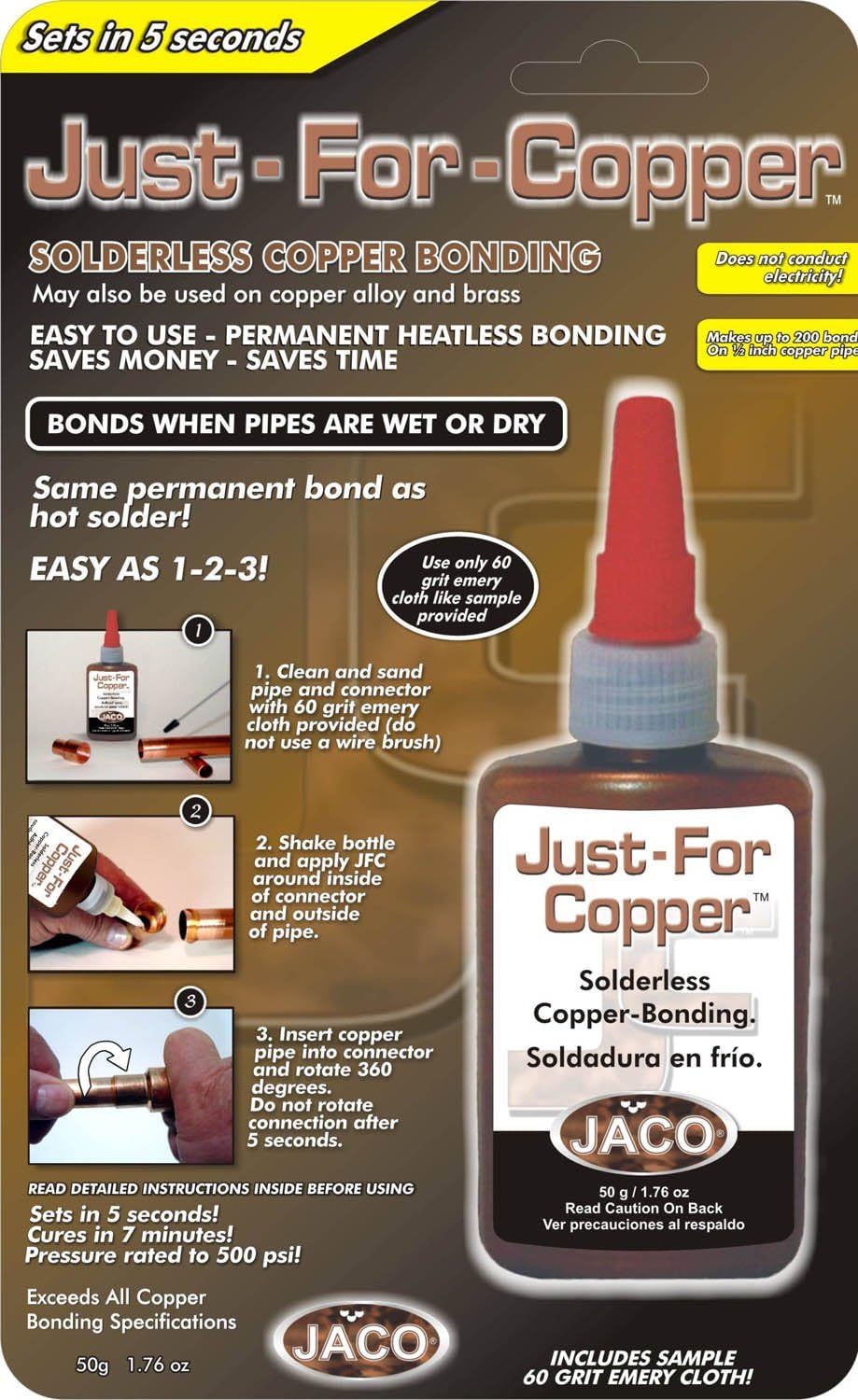

Jackson Industries 1.85 Oz Just For Copper Solderless Copper Bonding JFC050

FREE Shipping

Jackson Industries 1.85 Oz Just For Copper Solderless Copper Bonding JFC050

- Brand: Unbranded

Description

When you need to make adjustments, use the disconnecting tongs to remove the pipes from the connector. You will be able to reuse connectors according to the manufacturer’s directions. For example, SharkBite connectors can be reused up to 4 times. It’s also important to consult the manufacturer’s instructions before selecting an adhesive, as they may have specific recommendations on the type of copper pipe and conditions for optimal performance. Additionally, be sure to take into account the temperature and pressure that the pipes will be exposed to, as this can impact the longevity of the bond. By taking the time to carefully choose the right adhesive, you can avoid potential issues down the road and ensure a secure, long-lasting connection between your copper pipes. Preparing the Copper Pipes Before joining your pipes together without solder, it is very important to clean them thoroughly so they can form a tight seal. Start by wiping down the outside of the pipe with a cloth or paper towel until it is free from dust and debris. Then use sandpaper or steel wool to lightly sand away any oxidation from inside the pipe ends before joining them together with your fitting. This step should not be overlooked, as oxidation can prevent the sealant tape from forming a tight bond between the two surfaces. Step 3: Apply Sealant Tape Using an adhesive to bond copper to copper or other alloys is often called cold soldering. It typically involves applying an adhesive substance to copper pipe fittings to hermetically seal the pieces. Here are some details of the different glues you can use on copper: Anaerobic Adhesives After you have finished cutting all the parts, you need to arrange the parts and accessories in the structural shape you want.

Leak Prevention: One of the most crucial reasons for properly gluing copper pipes is to prevent leaks as it leads to costly repairs and water wastage. Even a small leak can lead to serious damage to your property if it goes unnoticed for too long. The presence of excess water and moisture can lead to the growth of molds, which can cause serious health hazards. It is completely non-flammable, odourless and tasteless and will withstand pressure of 200 pounds per square inch after only 7 minutes.The bond will be maintained in temperatures ranging from -40 degrees C to a staggering 120 degrees C.

What are some crucial aspects you need to know beforehand?

But wait, there’s more. We’ll also explore push-fit fittings known for their simplicity and ease of use. With these innovative fittings, no tools are necessary – just give them a gentle push, and voila. You’ve got yourself a robust connection without any pesky soldering.

The curing time will vary depending on the adhesive you use, but typically it takes 1-2 hours for the glue to set and at least 24 hours for it to fully cure. 5. Do I need to use primer before applying the adhesive? Hold the pipes in place: Hold the pipes and fittings together for about 30 seconds to allow the adhesive to set a little. This will ensure that they do not come apart during the curing process. No, once a fitting has been glued it cannot be disassembled without risking damage to the pipes or the fitting itself. You will need to replace the fitting with a new one. 9. How do I know if I have a leak in the copper pipe?

Be the First to Share

By following these steps and tips, you can successfully glue copper pipes and enjoy a long-lasting plumbing system. Keep in mind that proper preparation and application of adhesives are crucial to achieving the desired results, so take your time and be meticulous in your work. Final Thoughts Soldering is a remarkable technique used in both plumbing and electronics to securely join metal components together. By melting a metal alloy called solder, a bond is formed between the parts being joined. Typically, solder is a combination of tin and lead, although there are lead-free alternatives available. The cause of this problem could be due to dirty or oily pipes. Clean and sand the pipes again before applying primer and cement. The bond is very strong and is suitable for all domestic copper installations but cannot be used to cold weld other metals. It also cannot be used on threaded connectors as the joint will be too wide to prevent oxygen being present. The sketch above Using clamps to secure the parts that you want to join can help ensure a better seal. Attach clamps immediately after applying the adhesive and assembling the parts. Keep the clamps in place until the adhesive is fully cured.

- Fruugo ID: 258392218-563234582

- EAN: 764486781913

-

Sold by: Fruugo