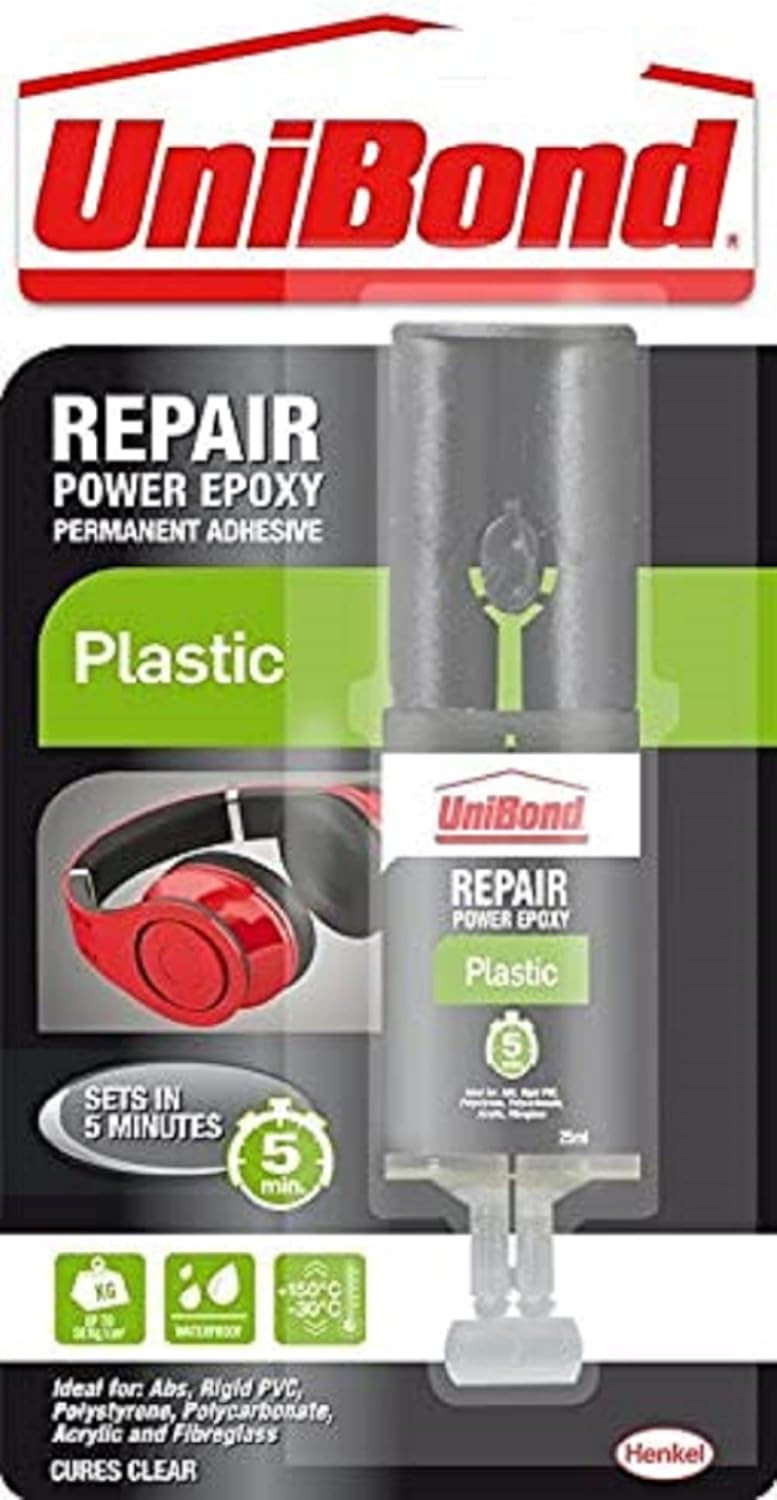

UniBond 1381190 Repair Power Epoxy Plastic - 25 ml

FREE Shipping

UniBond 1381190 Repair Power Epoxy Plastic - 25 ml

- Brand: Unbranded

Description

Thomas, Raju; Yumei, Ding; Yuelong, He; Le, Yang; Moldenaers, Paula; Weimin, Yang; Czigany, Tibor; Thomas, Sabu (2008-01-10). "Miscibility, morphology, thermal, and mechanical properties of a DGEBA based epoxy resin toughened with a liquid rubber". Polymer. 49 (1): 278–294. doi: 10.1016/j.polymer.2007.11.030. ISSN 0032-3861.

Always work in a space that is properly ventilated, many of the adhesives give off fumes and odors that could be harmful to you if you are not careful. Also, many of the adhesives are flammable, which makes working in a proper environment even more important. There are several kinds of glues that are suitable for gluing plastic. What is the best glue for plastic? The type you need depends on what you want to glue. One of the most popular and effective types are weld-on glues for plastics. Put on some gloves and safety goggles and clear the workspace. Put down a sheet to protect your surfaces. Epoxy resins typically require a precise mix of two components which form a third chemical to get the stated properties. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in usually they must be mixed exactly. The final product is then a precise thermoset plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature.

If you are looking for glue, sealant or insulation for any part of your vehicle, Amazing GOOP may cover all your needs. People ask These products are made to be tough, so removing them will not be the easiest thing to do, especially if you leave it until it hardens thoroughly. This is why you remove anything in the vicinity of your workspace you do not want glue to get on. Epoxy adhesives have many different qualities, including heat resistance and chemical resistance. And yes, there are also waterproof epoxy options for using on leaks, pools, and plumbing solutions. Water-soluble epoxies such as Durcupan [54] [55] are commonly used for embedding electron microscope samples in plastic so they may be sectioned (sliced thin) with a microtome and then imaged. [56] Art [ edit ] Here are the best glue for all kinds of plastic and many of them strongly bind other materials too.

Epoxy resins may be reacted ( cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing.With all glue use, we recommend gloves, mask and safety goggles, and in the case of aerosol-based adhesives we can’t stress this enough. Also as it’s an aerosol adhesive, remember that it’s highly flammable too, so storage in a safe, cool place is imperative. When the epoxy is still soft, it should be easier to remove. Take and use some acetone, which should help. Using a cloth with the acetone, wipe the area with the glue and it should eventually lift off. There are two main areas of marine use. Because of the better mechanical properties relative to the more common polyester resins, epoxies are used for commercial manufacture of components where a high strength/weight ratio is required. The second area is that their strength, gap filling properties and excellent adhesion to many materials including timber have created a boom in amateur building projects including aircraft and boats. It is made with tiny rubber particles that help increase its strength and impact resistance. Since it dries so fast, you never need to use clamps.

Epoxies have been modified in a variety of ways, including reacting with fatty acids derived from oils to yield epoxy esters, which were cured the same way as alkyds. Typical ones were L8 (80% linseed) and D4 (40% dehydrated castor oil). These were often reacted with styrene to make styrenated epoxy esters, used as primers. Curing with phenolics to make drum linings, curing esters with amine resins and pre-curing epoxies with amino resins to make resistant top coats. Organic chains maybe used to hydrophobically modify epoxy resins and change their properties. The effect of chain length of the modifiers has been studied. [45] Adhesives [ edit ] Special epoxy is strong enough to withstand the forces between a surfboard fin and the fin mount. This epoxy is waterproof and capable of curing underwater. The blue-coloured epoxy on the left is still undergoing curingEpoxy homopolymerisation is often used when there is a requirement for UV curing, since cationic UV catalysts may be employed (e.g. for UV coatings).

- Fruugo ID: 258392218-563234582

- EAN: 764486781913

-

Sold by: Fruugo